|  |

Features:

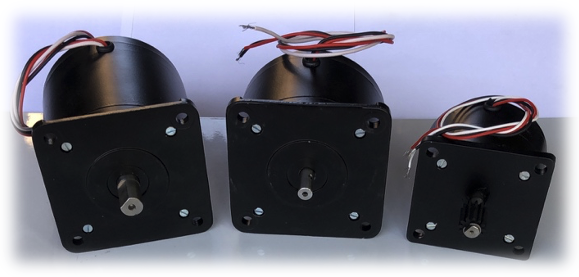

Servo-Step Synchronous / Stepper Motors represent a fusion of two dynamic motion control technologies, designed to deliver exceptional precision and versatility. These hybrid motors operate at low speeds but offer high torque, suitable for applications demanding fine control. With 200 discrete steps per revolution, they provide granular motion control, allowing for exact positioning - a feature immensely beneficial in industries like CNC machining, robotics, and automation.

When powered by AC, these motors function as synchronous motors, providing stable speed operation. Conversely, with DC pulses, they transform into stepping motors, offering precise incremental movements. This dual-mode functionality not only streamlines manufacturing processes but also reduces equipment complexity by eliminating the need for additional gear systems.

Their compact design and robust performance characteristics make them ideal for a wide range of industrial applications, including the precise movement of large hydraulic and pneumatic systems and the sophisticated motion control required in pharmaceutical and glass manufacturing.

Some of the unique features these versatile devices provide are:

- Can be controlled by digital drives.

- A dual-purpose product with many applications serving as

- Synchronous motor when supplied with AC power.

- Stepping motor when supplied with DC pulses using a translator.

- Bi-directional operations on AC or DC application.

- Compact design provides higher performance for higher torque output as compared to conventional motors.

- High torque & low speed characteristic of the motor eliminates the need of complex gear system.

- When used with AC supply

- Exhibits instant START-STOP-REVERSE direction characteristics.

- Operates at 1.2 times the line frequency with the help supplied RC Network.

- Due to non-existent “InRush” current when starting or “High current” when stalled, motors are protected from any damage thus prolonging it’s life with “No Degradation” of performance.

- When used with DC supply

- Moves 1.8 degrees (one step) for every pulse.

- With Solid State Translator, provides a huge gain over the microwatts of control power.

- When used with DC supply

Applications:

This motor has wide range of control system applications, such as

- Remote operation of huge hydraulic & pneumatic valves

- CNC machines Motion control in processing machines such as

- Printing machines

- Any application where controlled & precise linear motion is needed such as

- Pharmaceutical, Glass product manufacturing

- Any application where controlled & precise linear motion is needed such as

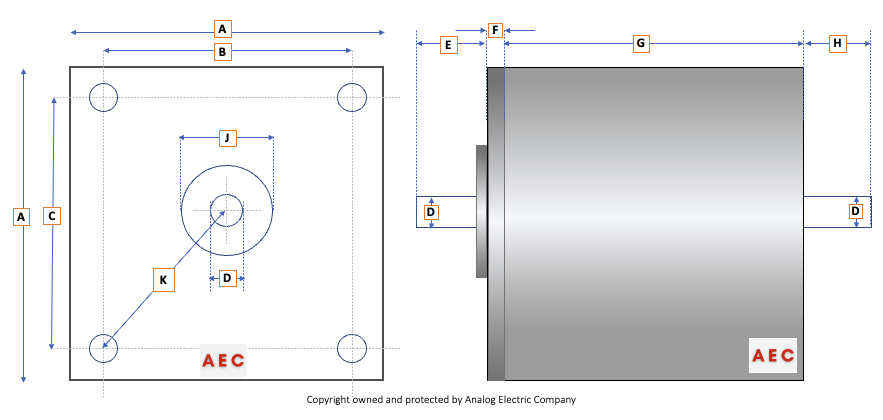

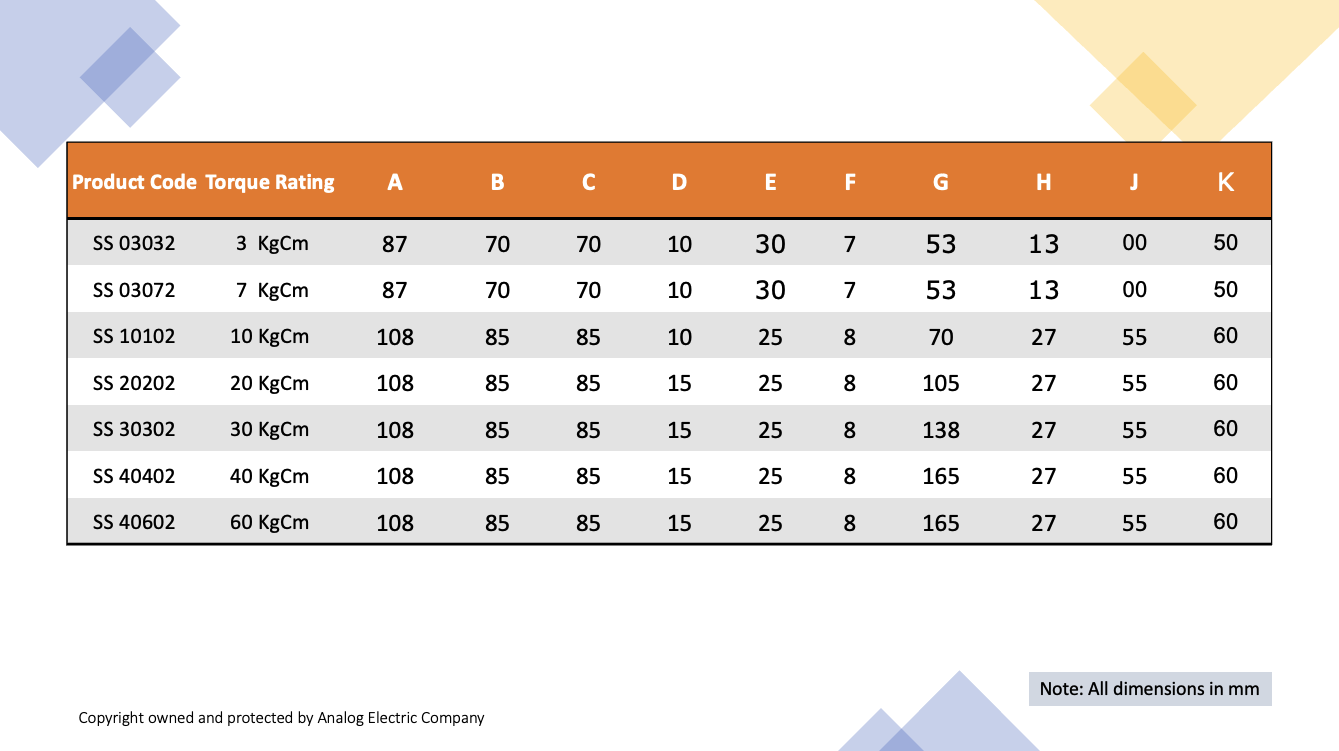

Product Dimensions: